Page 28 - February1999

P. 28

26 N,\Tn0NAn B{J1l1f0N B{Jn n ETIN February 1999

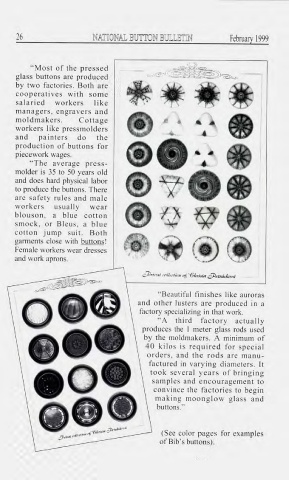

"Most of the pressed

glass buttons are produced

by two factories. Both are

cooperatives with some

salaried workers like

managers, engravers and

moldmakers. Cottage

workers like pressmolders

and painters do the

production of buttons for

piecework wages.

"The average press-

molder is 35 to 50 years old

and does hard physical labor

to produce the buttons. There

are safety rules and male

workers usually wear

blouson, a blue cotton

smock, or Bleus, a blue

cotton jump suit. Both

garments close with buttons!

Female workers wear dresses

and work aDrons.

"Beautiful finishes like auroras

and other lusters are produced in a

factory specializing in that work.

"A third factory actually

produces the I meter glass rods used

by the moldmakers. A minimum of

40 kilos is required for special

orders, and the rods are manu-

factured in varying diameters. It

took several years of bringing

samples and encouragement to

convince the factories to begin

making moonglow glass and

buttons."

(See color pages for examples

of Bib's buttons).