Page 48 - May1954

P. 48

238 NATIONAL BUTTON BULLETIN May, 1954

MODERN INLAY BUTTONS

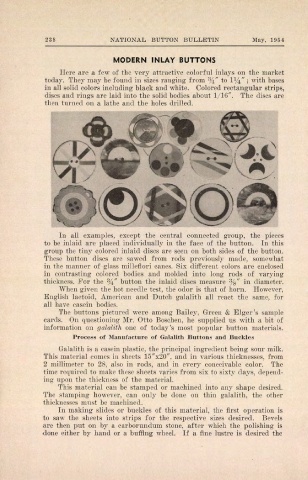

IJere are a few of the very attractive colorful inlal's on the market

today. They may be found in sizes ranging from.)/a" to 7r/+"; rvith bases

in all solid colors including black and white. Colored rectangular strips,

discs anil rings are laid into the solicl bodies about 1/16". The discs are

then turtecl on a lathe and the holes drilled.

I

In all examples, except the central connected group, the pieces

to be inlaid are placed individually in the face of the button. In this

group the tinyr gq1et.,1 inlaid discs are seelr or1 both sides of the button.

These button discs are sawed from rocls previousl;,' macle, somervhat

irr the manner of glass millefiori canes. Six clifferent colors are enclosed

in contrasting colored boclies ancl moltled into long rods of var;ting

thickrress. .F'or the 3/"" bttton the inlaicl discs rneasure 3/s" in cliameter.

\Yhen giverr the hot needle test, the odor is that of horn. IIowever,

English lactoicl, American and Dutch galalith all react the same, for

all have casein bodies.

The buttons pictured were among Baiiey, Green & Elger's sample

cards. On questioning Mr. Otto Boschen, he supplied us rvith a bit of

information or galal'itlt olte of today's most poltular button materials.

Process of Nlanufacture of Galalith Buttons and Buckles

Galalith is a casein piastic, the principal ingreclient being sour milk.

'This

material <rornes iir sheets 15"x20", and in I'arious thicknesses, from

2 miilimeter to 28, also in rods, arrd in everl' conceivable color. The

time recluirecl to mahe these sheets varies from six to sixtl' days, cleDeucl-

ittg' upon the thickness of the material.

This material can be stampccl or machinecl into any shape desired.

The stamping horvever, can only' be tlone on thil galalith, the other

thicknesses must be machined.

In making slides or buckles of this material, the first operation is

to saw the sheets iuto strips fol the respective sizes desired. Bevels

are then put on bJ' u .utbotunclum stone, aftelwhich the polishing is

done either by hand or a bufflng wheel. ff a fine lustre is desired the